Process Industry

Filling Line

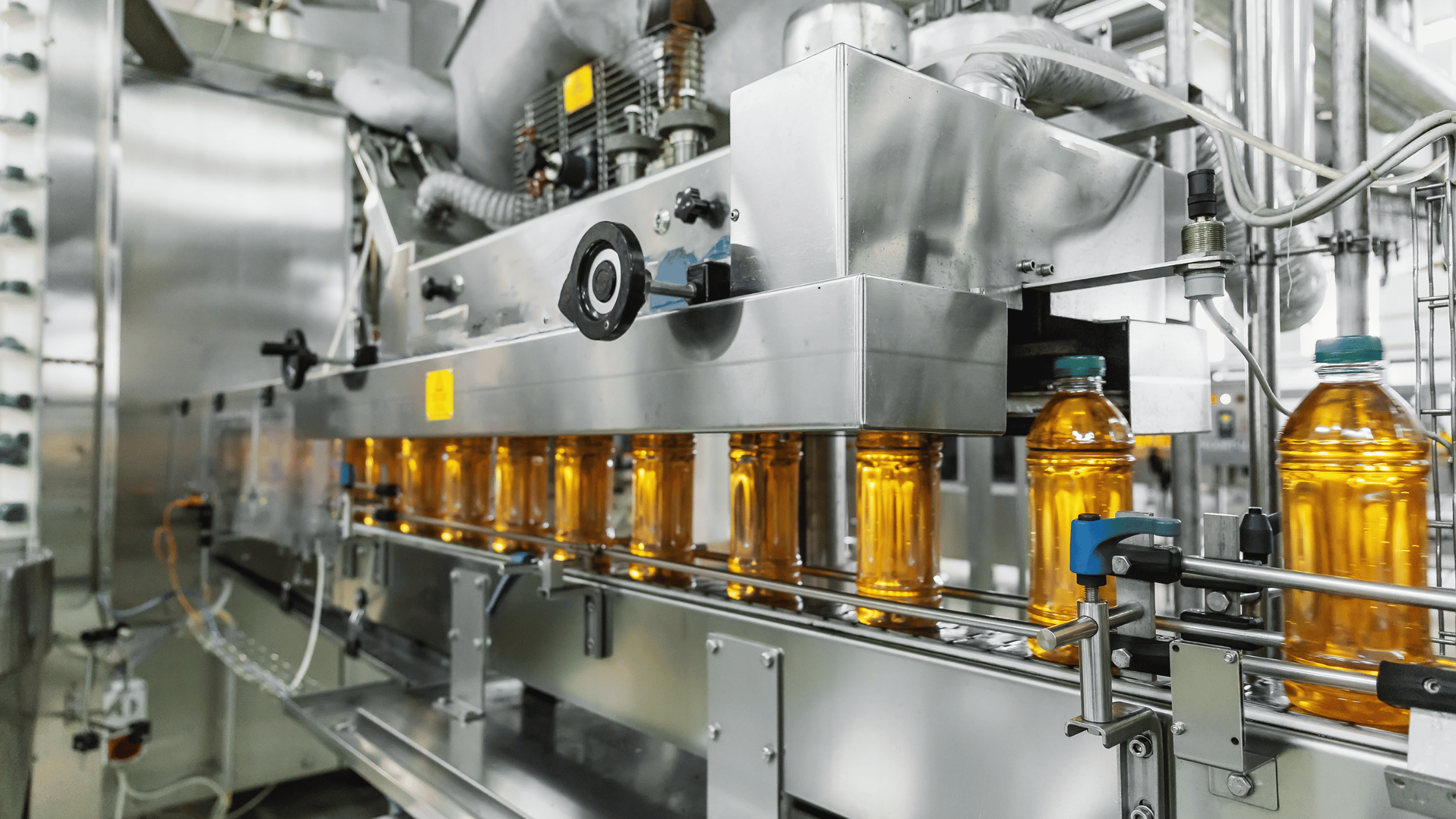

FILLING LINE in the Food Industry plays a vital role in automating the precise filling of containers with liquids, sauces, or dry ingredients. Designed for speed and accuracy, modern filling lines reduce waste, improve efficiency, and ensure consistent product quality—key in a highly regulated industry where hygiene and safety are critical.

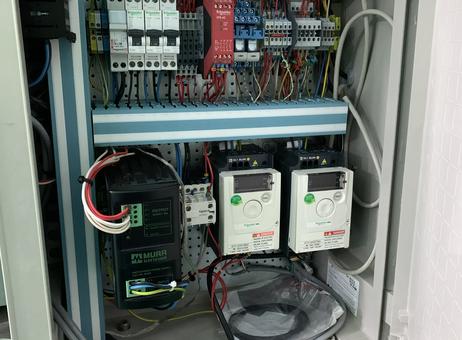

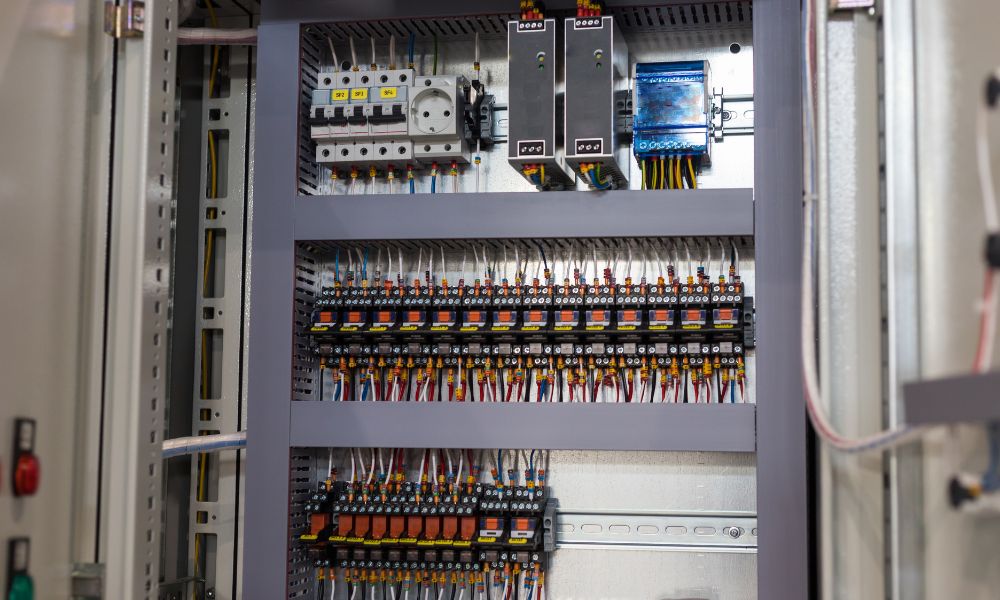

Electrical Control Panels are essential to this system, managing the coordination and performance of filling equipment. They enable operators to adjust filling speeds, monitor operations in real time, and ensure smooth, reliable output. By integrating control panels, food manufacturers enhance automation, maintain compliance with safety standards, and optimize overall production efficiency.

Weighing Machines

WEIGHING MACHINES are vital in the food industry for accurately measuring ingredients and finished products. They help maintain portion control, ensure product consistency, and support compliance with quality and safety standards. With advanced technology, modern weighing machines deliver precise measurements and real-time data, minimizing waste and enhancing production efficiency.

Electrical Control Panels support these machines by managing calibration, settings, and performance monitoring. They allow operators to adapt quickly to different products and optimize weighing processes. Together, weighing machines and control panels ensure accurate, efficient, and compliant food production that meets consumer expectations.

Packing Lines

PACKING LINES are essential in the food industry, automating the filling, sealing, and labeling of products with speed and precision. These systems improve productivity, reduce labor costs, and ensure consistent, safe packaging — all critical for meeting industry standards and consumer expectations.

Supporting this process are Electrical Control Panels, which manage and monitor packing line operations. They allow real-time adjustments, track performance data, and help prevent downtime through early issue detection. Together, packing lines and control panels streamline food packaging, enhance quality control, and ensure efficient, compliant production.

Labelling Machines

LABELLING MACHINES are essential in the food industry, automating the precise application of labels on packaging. These machines ensure consistency and compliance with labeling regulations, including ingredient lists, nutritional facts, and expiration dates. With advanced features like sensors and automated alignment, they improve efficiency, reduce manual labor, and support brand presentation and consumer trust.

Working in tandem, Electrical Control Panels manage the machine’s functions—controlling speed, alignment, and operational settings. These panels enable real-time monitoring, quick adjustments, and seamless integration into larger packaging systems. Together, labelling machines and control panels boost accuracy, streamline production, and uphold quality in food packaging.

Process Industry

How can we help you?

We’re just a message away—reach out for more information!