Mining Industry

Horizontal Belt Filter

Horizontal Belt Filters (HBF) are industrial machines designed for continuous and efficient solid-liquid separation. In this process, slurry is distributed over a moving horizontal belt supported by a vacuum system. As the liquid is drawn through the filter cloth, solids remain on the belt, forming a filter cake. HBFs are widely used in industries such as mining, chemicals, and food processing to reduce moisture content and recover filtrate efficiently.

These filters offer high throughput, can handle diverse slurry types, and support multi-stage washing to enhance product purity. With low operating costs and consistent performance, HBFs are a reliable choice for industrial filtration needs.

Lab Filter Press

Lab Filter Press is a compact device used for small-scale solid-liquid separation in laboratory settings. It works by applying pressure to a slurry, forcing liquid through a filter cloth while retaining solids. Ideal for R&D, quality control, and pilot testing, it’s widely used in industries like pharmaceuticals, chemicals, and mining.

The Lab Filter Press offers precise handling of small samples, quick setup and cleanup, and supports evaluation of filtration efficiency, cake formation, and moisture levels—making it a key tool for process optimization before industrial scale-up.

Filteration Jig

Filtration Jig is a specialized device used for density-based solid-liquid separation, commonly in mineral processing. It operates with a pulsating water flow that stratifies materials—heavier particles settle at the bottom while lighter ones rise—enabling efficient separation and recovery of valuable minerals.

Key benefits include high throughput, low maintenance, and effective fine particle recovery. Ideal for ores, coal, and similar materials, the Filtration Jig supports continuous operation, making it a cost-effective and reliable solution in industrial separation processes.

Its compact design allows for easy integration into existing systems, while adjustable settings offer flexibility to handle various material types and separation needs. As industries prioritize resource efficiency and quality output, filtration jigs continue to be an essential part of modern processing lines.

Casting Machine

Casting Machine is an industrial tool used to shape materials—typically molten metal—by pouring them into molds where they solidify into specific forms. These machines are vital in industries like automotive, aerospace, and metal foundries, offering precision and consistency in producing complex components with high-quality finishes.

Various casting methods, such as die casting, investment casting, and centrifugal casting, are employed based on material type and application. These machines support a wide range of materials including metals, plastics, and ceramics.

Key advantages include reduced material waste, high repeatability, and efficient mass production. Modern casting machines often feature automated controls, temperature regulation, and real-time monitoring, ensuring accuracy, improving safety, and enhancing overall productivity.

Ladle Tilter

A Ladle Tilter is a specialized industrial device used to pour molten metal from a ladle into molds or other containers during the casting process. It is designed to handle heavy loads and tilt the ladle at controlled angles, allowing for precise and safe pouring. The Ladle Tilter is widely utilized in foundries and steel plants to improve the efficiency of metal casting operations while minimizing spillage and ensuring accurate flow control. Its robust construction and reliable mechanism make it suitable for handling high-temperature molten materials.

The main advantages of using a Ladle Tilter include enhanced operator safety, reduced labor effort, and improved control over the pouring process. By allowing gradual tilting and smooth flow of the molten metal, it minimizes turbulence and reduces the risk of defects in the final cast products. Additionally, the Ladle Tilter can be integrated with automation systems to further optimize the casting process, ensuring consistency and high-quality output in industrial metalworking applications.

Tapping Platform

Tapping Platform is a robust industrial structure used in metallurgical operations to safely extract molten metal from furnaces such as blast or electric arc furnaces. It provides a stable, heat-resistant workspace where operators can manage the controlled flow of molten metal into ladles or containers for further processing.

Designed with operator safety in mind, the platform often includes protective barriers, remote-controlled tools, and ergonomic access to critical equipment. Its use helps maintain precision in tapping, ensuring metal quality and proper chemical composition.

Advanced Tapping Platforms may feature automation and integrated slag handling systems, enhancing consistency, reducing downtime, and streamlining operations in high-temperature environments.

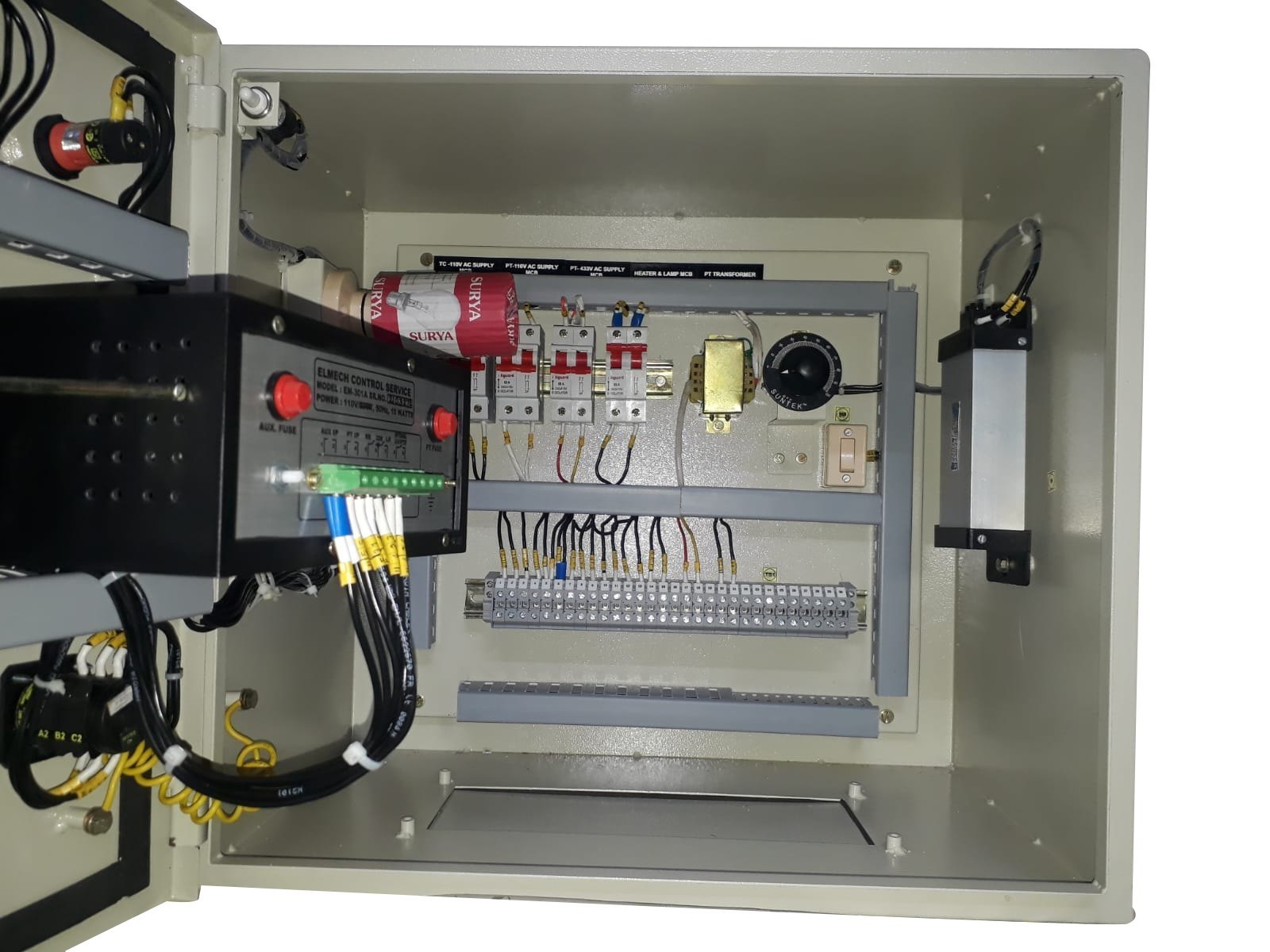

Process Automation For Metal Recovery Plant

Process Automation in a Metal Recovery Plant involves integrating advanced control systems to efficiently recover valuable metals from ores, scrap, or waste. This automation optimizes critical parameters like temperature, pressure, and chemical composition, ensuring consistent, high-quality output. Key technologies such as Programmable Logic Controllers (PLCs), SCADA systems, and robotic equipment automate operations including crushing, grinding, leaching, and smelting.

The advantages of automation include increased productivity, reduced operational costs, and enhanced safety. By minimizing manual intervention, it ensures greater accuracy and reliability while reducing the risk of human error. Real-time data monitoring and predictive maintenance help prevent downtime and improve overall plant performance. Ultimately, automation leads to higher metal recovery rates, better resource utilization, and a more sustainable, cost-effective operation.

Mining Industry

How can we help you?

We’re just a message away—reach out for more information!