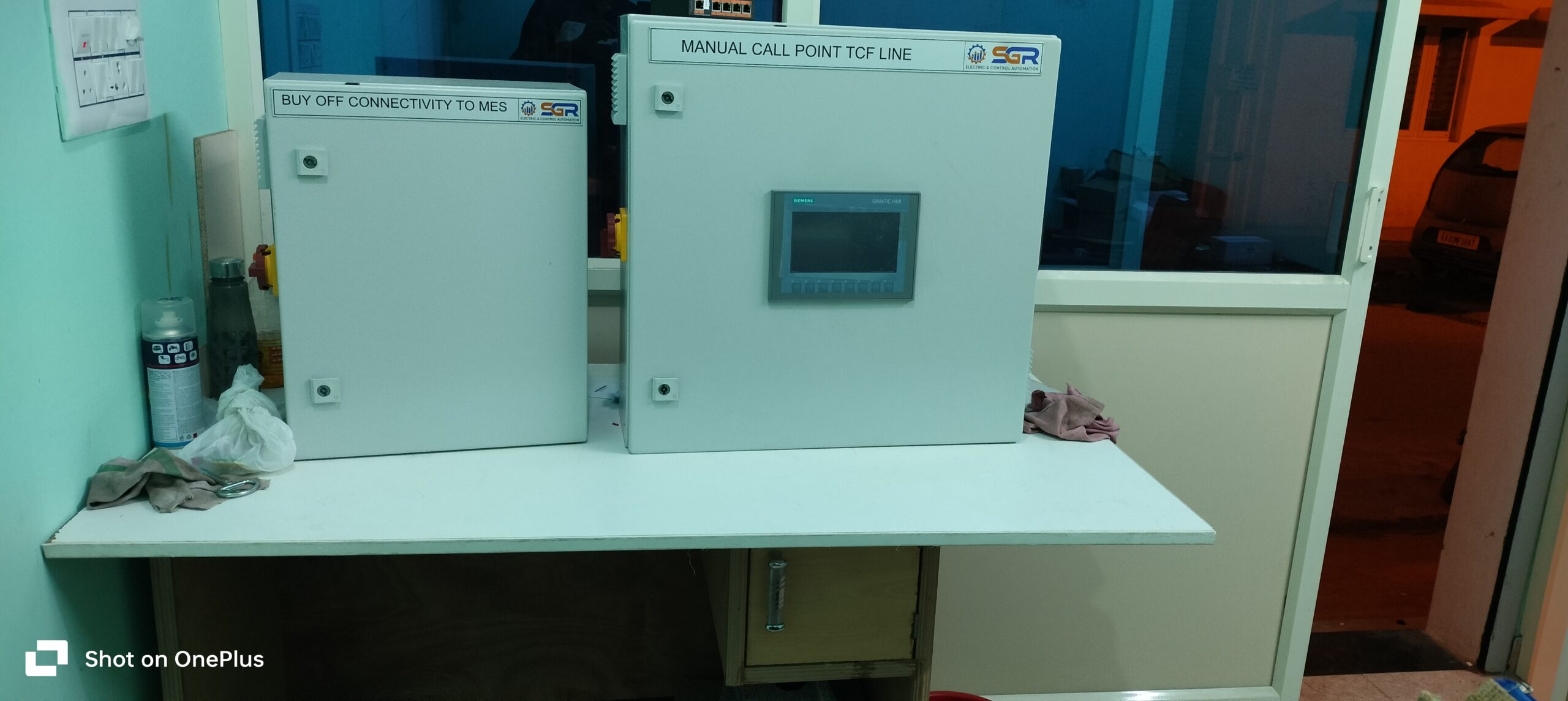

PLC Automation Panel

PLC Automation Panels

PLC (Programmable Logic Controller) automation panels are key components in industrial automation, serving as centralized control systems for machinery and processes. They enable automated management of tasks like monitoring, controlling, and optimizing equipment operations, replacing traditional relay-based systems with more efficient and flexible solutions.

A typical PLC automation panel includes a PLC unit, input/output (I/O) modules, power supplies, and communication interfaces. The PLC executes pre-programmed instructions based on signals from sensors, while I/O modules handle data exchange between field devices and control elements like actuators and motors, ensuring smooth system coordination.

One major advantage of PLC panels is their programmability, which allows for easy updates and modifications without rewiring. This makes them highly adaptable to changing production needs. They support multiple programming languages such as ladder logic and function block diagrams, making them user-friendly for engineers and technicians alike.

Safety is a key priority in these panels. Features like emergency stops, interlocks, and safety relays are built in to protect workers and equipment. Regular maintenance and compliance with safety standards ensure safe and reliable operation in demanding industrial settings.

In summary, PLC automation panels offer a flexible, programmable, and safe solution for managing complex industrial systems. They enhance efficiency, support rapid changes, and are central to modern, intelligent manufacturing.

Industries

How can we help you?

We’re just a message away—reach out for more information!