Textile Industry

GE & MB Assembly Line

The GE & MB Assembly Line is a modern, high-efficiency manufacturing system that leverages advanced automation to streamline production. Equipped with robotic systems and intelligent software, the line delivers faster assembly with consistent quality, reducing both production time and operational costs.

Designed for flexibility, it allows quick adaptation to shifting market demands—an essential advantage in today’s fast-changing industrial landscape. The system also emphasizes operator safety and ergonomics, incorporating features that reduce physical strain and improve workplace conditions. With its focus on precision, adaptability, and worker well-being, the GE & MB Assembly Line is a powerful solution for next-generation manufacturing

paint shop monitor system

The Paint Shop Monitor System is a smart solution designed to optimize paint application processes in manufacturing. It offers real-time monitoring of key parameters like paint viscosity, temperature, and spray rates, helping ensure consistent quality and early detection of potential issues. With integrated sensors and automated data reporting, the system supports strict adherence to quality standards and reduces the likelihood of defects.

Beyond quality control, the system enhances operational efficiency by minimizing paint waste and improving resource usage. It provides actionable insights to fine-tune workflows and manage inventory more effectively by tracking paint consumption and issuing low-supply alerts. As industries focus on sustainability and precision, the Paint Shop Monitor System proves essential for achieving high-quality finishes while streamlining production.

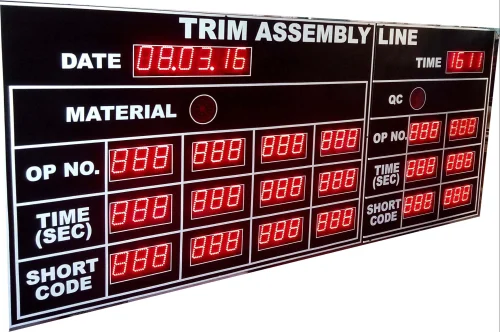

Andon Display for maintenance

Andon Display for Maintenance is a crucial tool in modern manufacturing, designed to improve communication and streamline maintenance operations. It provides real-time, visual updates on equipment status, production progress, and maintenance alerts, using color-coded signals to help teams quickly identify and address issues. This immediate visibility reduces downtime and supports proactive maintenance efforts.

Beyond faster response times, the system promotes transparency and accountability on the shop floor. Operators are encouraged to report anomalies, fostering collaboration between production and maintenance teams. This results in better equipment care, improved efficiency, and higher overall productivity. As factories move toward smarter operations, the Andon Display remains a key asset in maintaining peak performance and operational reliability.

Merceside Yarn making machine

MERCESIDE Yarn Making Machine is a cutting-edge solution for producing premium-quality yarns in the textile industry. Designed for precision and efficiency, it features automated tension control and variable spinning speeds, enabling consistent output across a wide range of yarn types. Its advanced technology ensures reliable performance that meets high-quality standards.

In addition to productivity, the MERCESIDE machine emphasizes sustainability by minimizing waste and reducing energy consumption. Its user-friendly interface offers real-time monitoring, allowing quick adjustments and smooth operation. As the demand for sustainable and high-efficiency textile manufacturing grows, the MERCESIDE Yarn Making Machine proves to be an essential asset for forward-thinking manufacturers.

Industries

How can we help you?

We’re just a message away—reach out for more information!